Professor Nejat Olgac received an honorary doctorate from the Czech Technical University in Prague during a ceremony that took place on January 29, 2019.

Professor Nejat Olgac received an honorary doctorate from the Czech Technical University in Prague during a ceremony that took place on January 29, 2019.

Read more on the School of Engineering’s website.

Professor Nejat Olgac received an honorary doctorate from the Czech Technical University in Prague during a ceremony that took place on January 29, 2019.

Professor Nejat Olgac received an honorary doctorate from the Czech Technical University in Prague during a ceremony that took place on January 29, 2019.

Read more on the School of Engineering’s website.

Prof. Jiong Tang will serve as the general conference chair for the American Society of Mechanical Engineers’ international annual design conference in Anaheim CA. The 2019 ASME International Design Engineering Technical Conference (IDETC) and Computers and Information in Engineering Conference (CIE) will take place between August August 18 – 21, 2019 at the Anaheim Convention Center.

Prof. Jiong Tang will serve as the general conference chair for the American Society of Mechanical Engineers’ international annual design conference in Anaheim CA. The 2019 ASME International Design Engineering Technical Conference (IDETC) and Computers and Information in Engineering Conference (CIE) will take place between August August 18 – 21, 2019 at the Anaheim Convention Center.

(via UConn Today)

Stephanie Knowlton and Reza Amin, both engineering doctoral students working with Prof. Savas Tasoglu, won first prize in the 2018 Wolff New Venture Competition to develop QRfertile – an in-home device to measure male fertility.

Read more at UConn Today.

The new UConn AIAA student chapter competed for the first time in the Spaceport America Cup during the summer of 2018. Advised by ME professor, Dr. Jackie Sung, the students designed and built a rocket for the competition. More details on the School of Engineering website.

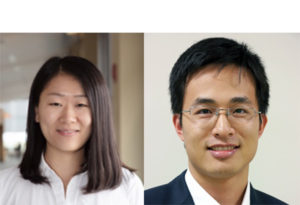

ME graduate student Dan Wang and Professor Xu Chen won the Best Paper (Theory) of the 2018 International Symposium on Flexible Automation (ISFA) for their paper titled “Synthesis and Analysis of Multirate Repetitive Control for Fractional-order Periodic Disturbance Rejection in Powder Bed Fusion.”

ME graduate student Dan Wang and Professor Xu Chen won the Best Paper (Theory) of the 2018 International Symposium on Flexible Automation (ISFA) for their paper titled “Synthesis and Analysis of Multirate Repetitive Control for Fractional-order Periodic Disturbance Rejection in Powder Bed Fusion.”

The ISFA started in 1986 under the co-sponsorship of the American Society of Mechanical Engineers (ASME) and the Institute of Systems, Control and Information Engineers (ISCIE) in Japan. The symposium focuses on automation technologies that are essential to meet the increasing requirements of modern manufacturing and other related fields, such as dynamical systems, robotics, logistics, biomedical systems, and healthcare systems.

The 2018 symposium was held in Kanazawa, Japan from July 15 to July 19. Every year the symposium recognizes two best papers appearing in the Proceedings and presented at the Symposium. One award emphasizes contribution to theory, and the other emphasizes significant or innovative applications/practice. Criteria for selection include the quality of the written and oral presentation, the technical contribution, timeliness, and practicality. Each award consists of a certificate and an honorarium of $1,000.

Wang and Chen’s paper discusses control approaches to advance the quality of repetitive energy deposition in powder bed fusion (PBF) additive manufacturing, pertaining specifically to the repetitive deposition of the laser or electron beam energy. It addresses an intrinsic limitation in control schemes that can leverage the periodicity of task patterns to significantly improve system performance. The long-term impacts will include greater quality assurance of the manufactured parts, new capabilities for large-scale 3D printing of extreme materials, and smarter machines and automation in additive manufacturing processes.

Dr. Michael Pettes and his graduate student Wei Wu have significantly improved the performance of an atomically thin semiconductor material by stretching it, an accomplishment that could prove beneficial to engineers designing the next generation of flexible electronics, nano devices, and optical sensors. The findings mark the first time scientists have been able to conclusively show that the properties of atomically thin materials can be mechanically manipulated to enhance their performance, Pettes says. Such capabilities could lead to faster computer processors and more efficient sensors. The process the researchers used to achieve the outcome is also significant in that it offers a reliable new methodology for measuring the impact of strain on ultrathin materials, something that has been difficult to do and a hindrance to innovation. More information is available at UConn Today: http://s.uconn.edu/4ad

Two ME professors received the 2018 National Science Foundation’s CAREER award, which is the Foundation’s most prestigious award in support of early-career faculty.

Prof. Xu Chen’s award will support his research on thermal modeling, sensing, and controls to enable new generations of powder bed fusion (PBF) additive manufacturing. In contrast to conventional machining, where parts are made by cutting away unwanted material, additive manufacturing — also called 3D printing — builds three-dimensional objects of unprecedented complexity by progressively adding small amounts of material. PBF is a popular form of AM for fabricating complex metallic or high-performance polymer parts. This CAREER project will create new knowledge critical for substantially higher accuracy and greater reproducibility in PBF and AM. Building on innovations to model and control the thermal mechanical process, the research will illuminate ways to mitigate quality variations on the fly, and provide new feedback-centric control paradigms to engineer the layered deposition of thermal energy, which is imperative for quality and reproducibility. PBF parts are increasingly preferred in applications ranging from advanced jet-engine components to custom-designed medical implants. The outcomes of this project will facilitate fabrication of products to benefit the US economy and improve quality of life. More broadly, methods and tools developed from this research has the potential to drastically impact the manufacturing of a wide range of components for the energy, aerospace, automotive, healthcare, and biomedical industries that can benefit from short-run high-quality production.

Prof. Norato’s award will support fundamental research to formulate a design framework to systematically incorporate geometric design rules and manufacturing cost considerations into the computational design of structures. In particular, the techniques advanced in this project belong to a group of techniques called topology optimization, in which a computer program finds the optimal shape of a structural component or an architected material. This research will enable the conceptual design and optimization of lightweight, high-performance, and economically-viable structures with applications across a wide range of engineering industries. The new design capabilities will have the potential to significantly reduce manufacturing and R&D costs and thereby increase the economic competitiveness of American manufacturers. Prof. Norato is also a recipient of the 2017 ONR Young Investigator Award.

Both awards are for five years and approximately $500,000 (minimum), and have an outreach component towards K-12 students and people from underrepresented communities.

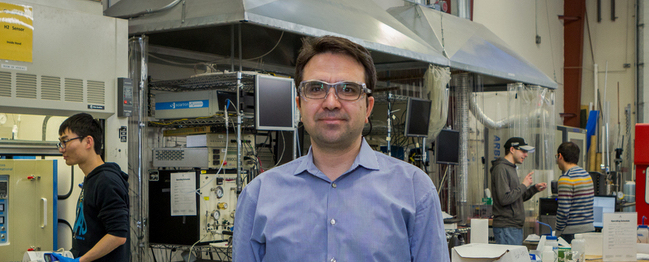

The new grant funded by the US Department of Energy supports new graduate programs in Mechanical Engineering to train the next generation of advanced manufacturing leaders. The UConn effort has been led by Prof. Ugur Pasaogullari.

More details can be found on the School of Engineering website.