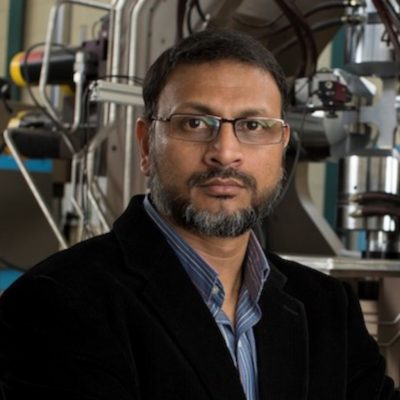

Dr. Wajid Chishty joined our school as an in-residence Full Professor in January 2023. In the realm of academia, Dr. Wajid Chishty has consistently demonstrated exceptional accomplishments. He earned his MBA in Finance from The University of Karachi in 1991, followed by an MS degree in Aerospace Engineering from the University of Michigan in 1996. In 2005, he obtained his PH.D in Mechanical Engineering from Virginia Polytechnic & State University.

Dr. Wajid Chishty joined our school as an in-residence Full Professor in January 2023. In the realm of academia, Dr. Wajid Chishty has consistently demonstrated exceptional accomplishments. He earned his MBA in Finance from The University of Karachi in 1991, followed by an MS degree in Aerospace Engineering from the University of Michigan in 1996. In 2005, he obtained his PH.D in Mechanical Engineering from Virginia Polytechnic & State University.

With over three decades of engineering experience under his belt, Dr. Chishty brings a wealth of expertise to our department. His primary areas of expertise include “gas turbine maintenance”, where he applies his skills to aerospace engines, and combustion research which is a study about how things burn; a field crucial for enhancing the environmental efficiency of aerospace engines.

Beyond his professional achievements, Professor Chishty is an active contributor to academia. Chishty is an educator who has authored numerous publications in topics surrounding engineering mechanics, with a portfolio of more than 50 research papers.

Dr. Chishty is a respected member of several esteemed organizations, including the American Society of Mechanical Engineering (ASME) who are dedicated to promoting “the art, science and practice of multidisciplinary engineering and allied sciences” (asme.org) worldwide. He is also affiliated with the American Society for Engineering Education (ASEE), a non-profit founded in 1893 aimed at advancing engineering and its education practices. Additionally, Dr Chishy is a member of the American Institute of Aeronautics and Astronautics (AIAA), a U.S representative of the International Astronautical Federation and the International Council of Aeronautical Sciences.

Mishu Duduta‘s academic journey is truly remarkable. He earned his Bachelor’s degree in Material Science from MIT in 2010, demonstrating his early passion for science. Dr. Duduta graduated in 2019 with an Engineering Sciences PhD degree from Harvard University, with a thesis titled “Dielectric Elastomer Actuators as Artificial Muscles for Soft Robotic Applications.” His outstanding research earned him the prestigious Gold Award from the Materials Research Society in 2018 and a nomination for Best Paper at ICRA. Dr. Duduta’s list of awards and grants is extensive, with support from foundations both nationally and internationally. His contributions to research have led to multiple publications and citations, solidifying his presence in the academic world.

Mishu Duduta‘s academic journey is truly remarkable. He earned his Bachelor’s degree in Material Science from MIT in 2010, demonstrating his early passion for science. Dr. Duduta graduated in 2019 with an Engineering Sciences PhD degree from Harvard University, with a thesis titled “Dielectric Elastomer Actuators as Artificial Muscles for Soft Robotic Applications.” His outstanding research earned him the prestigious Gold Award from the Materials Research Society in 2018 and a nomination for Best Paper at ICRA. Dr. Duduta’s list of awards and grants is extensive, with support from foundations both nationally and internationally. His contributions to research have led to multiple publications and citations, solidifying his presence in the academic world.

Prior to joining UConn in August 2023 as an Assistant Professor, Professor Duduta enriched his academic and professional journey with diverse experiences. After completing his post-doctoral studies at the University of Minnesota, Medical Devices Innovation Fellow where he developed a soft robotic tools for neurointervention. He served as an Assistant Professor at The University of Toronto. His pioneering work in developing the biomedical tool showcases his dedication to innovation in the field. Currently, he leads the Duduta Research Group, known for its pioneering work in biomedical robotics and its global recruitment of Ph.D. students.

Chang Liu joined our school as an Assistant Professor in August 2023. Dr. Liu’s educational journey commenced at Shanghai Jiao Tong University in 2017, where he earned not one, but two Bachelor’s degrees in Naval Architecture and Ocean Engineering as well as Computer Technology and its Applications. However, Liu’s desire for knowledge did not end there. He continued his educational pursuit, obtaining a Master’s in Mechanical Engineering in 2020 and a Master of Science in Applied Mathematics and Statistics in 2021 at Johns Hopkins University. In a testament to his dedication and scholarly prowess, Liu successfully completed his Ph.D. in Mechanical Engineering also in 2021 at JHU.. Subsequently, he embarked on postdoctoral research at the University of California, Berkeley from 2021 to 2023.

Chang Liu joined our school as an Assistant Professor in August 2023. Dr. Liu’s educational journey commenced at Shanghai Jiao Tong University in 2017, where he earned not one, but two Bachelor’s degrees in Naval Architecture and Ocean Engineering as well as Computer Technology and its Applications. However, Liu’s desire for knowledge did not end there. He continued his educational pursuit, obtaining a Master’s in Mechanical Engineering in 2020 and a Master of Science in Applied Mathematics and Statistics in 2021 at Johns Hopkins University. In a testament to his dedication and scholarly prowess, Liu successfully completed his Ph.D. in Mechanical Engineering also in 2021 at JHU.. Subsequently, he embarked on postdoctoral research at the University of California, Berkeley from 2021 to 2023.

Liu’s research centers on unraveling and harnessing the complex dynamics of fluids and gasses, such as the flow of water in rivers or the turbulence, when the water gets choppy. His primary objectives are to decipher methods for controlling these intricate forces and forecasting their behaviors.

Prof. Jackie Sung was awarded the 2024 AIAA Energy Systems Award for his significant contribution in the broad field of energy systems, and specifically for his outstanding contributions to flame dynamics and low-temperature chemistry for developing fuel-flexible, ultra-low emission, efficient combustion energy systems using conventional and alternative fuels.

Prof. Jackie Sung was awarded the 2024 AIAA Energy Systems Award for his significant contribution in the broad field of energy systems, and specifically for his outstanding contributions to flame dynamics and low-temperature chemistry for developing fuel-flexible, ultra-low emission, efficient combustion energy systems using conventional and alternative fuels. Abstract: Recent decades have seen rapid development in all manufacturing technologies, including additive manufacturing (AM). This has raised the need for design methods to leverage the new, increasingly complex fabrication possibilities. Topology optimization has the potential to generate new high-performing design solutions since it is a free-form design method that does not require a preconceived notion of the final layout. It uses computational mechanics and optimization tools to generate improved designs. For operating designs to perform as predicted, the used model must capture the material behavior. Additionally, the planned manufacturing process might induce material characteristics and design limitations that should be considered as the design is generated. This talk focuses on identifying and incorporating behavioral and manufacturing aspects within the design process. Different strategies for integration within topology optimization will be discussed. This includes consideration of manufacturing-induced material characteristics, which is illustrated through tailoring design to material extrusion-based AM. In material extrusion, a nozzle moves across a build plate and deposits a material bead on a 2D slice of the design. These processes typically induce some degree of anisotropy through weak(er) bonding between adjacent beads. To improve the manufacturability of large-scale designs, the application of a Mixed Integer Linear Programming formulation is discussed for highly restricted volume scenarios. Finally, a new design framework is introduced in which the interactive participation of the design engineer is enabled to resolve more complex mechanic phenomena.

Abstract: Recent decades have seen rapid development in all manufacturing technologies, including additive manufacturing (AM). This has raised the need for design methods to leverage the new, increasingly complex fabrication possibilities. Topology optimization has the potential to generate new high-performing design solutions since it is a free-form design method that does not require a preconceived notion of the final layout. It uses computational mechanics and optimization tools to generate improved designs. For operating designs to perform as predicted, the used model must capture the material behavior. Additionally, the planned manufacturing process might induce material characteristics and design limitations that should be considered as the design is generated. This talk focuses on identifying and incorporating behavioral and manufacturing aspects within the design process. Different strategies for integration within topology optimization will be discussed. This includes consideration of manufacturing-induced material characteristics, which is illustrated through tailoring design to material extrusion-based AM. In material extrusion, a nozzle moves across a build plate and deposits a material bead on a 2D slice of the design. These processes typically induce some degree of anisotropy through weak(er) bonding between adjacent beads. To improve the manufacturability of large-scale designs, the application of a Mixed Integer Linear Programming formulation is discussed for highly restricted volume scenarios. Finally, a new design framework is introduced in which the interactive participation of the design engineer is enabled to resolve more complex mechanic phenomena.