Click on the title to read more.

Author: Orlando E

Rescuing Drones From the Ocean

https://news.engr.uconn.edu/senior-design-journey-2020-rescuing-drones-from-the-ocean-part-1.php

Click on the title to read more.

Transforming Metal Casting Science for the 21 st Century – Role of 3D Design Principles and Smart Sand Molds

Abstract: Over 90% of all manufactured goods and machinery use a cast part. Sand casting is a manufacturing process that dates back to 1000 BC and accounts for 70% of all cast parts. Sand casting has several critical applications in a variety of sectors including defense, energy, aerospace and automotive. However, conventional sand casting is regarded as a process of uncertainty due to its tendency to render higher scrap rates even in completely controlled processing environments. Casting defect analysis shows that over 90% of casting defects occur due to improper gating and feeding systems. This talk will present a novel approach to rethink the design principles for: (1) sand cast parts and (2) gating and feeding systems to reduce defects in a given casting, alloy systems and pouring conditions. A systematic framework for the design, hybrid molding and instrumentation of molds for sand castings is presented for alloys of varying freezing ranges and pouring conditions. Results from numerical analysis, computational melt flow simulations and experimental evaluation show that 3D Sand-Printing can lower melt flow turbulence in castings which reduces casting defects (35% reduction) and improves as-cast mechanical properties (8.4% increase in flexural strength). Finally, early results from concurrent efforts to digitize the entire workflow of sand casting into wireless ‘Casting 4D’ is presented to visualize melt flow in sand molds.

Abstract: Over 90% of all manufactured goods and machinery use a cast part. Sand casting is a manufacturing process that dates back to 1000 BC and accounts for 70% of all cast parts. Sand casting has several critical applications in a variety of sectors including defense, energy, aerospace and automotive. However, conventional sand casting is regarded as a process of uncertainty due to its tendency to render higher scrap rates even in completely controlled processing environments. Casting defect analysis shows that over 90% of casting defects occur due to improper gating and feeding systems. This talk will present a novel approach to rethink the design principles for: (1) sand cast parts and (2) gating and feeding systems to reduce defects in a given casting, alloy systems and pouring conditions. A systematic framework for the design, hybrid molding and instrumentation of molds for sand castings is presented for alloys of varying freezing ranges and pouring conditions. Results from numerical analysis, computational melt flow simulations and experimental evaluation show that 3D Sand-Printing can lower melt flow turbulence in castings which reduces casting defects (35% reduction) and improves as-cast mechanical properties (8.4% increase in flexural strength). Finally, early results from concurrent efforts to digitize the entire workflow of sand casting into wireless ‘Casting 4D’ is presented to visualize melt flow in sand molds.

Biographical Sketch: Dr. Guha Manogharan is an Assistant Professor of Mechanical Engineering and an Affiliate Assistant Professor of Industrial and Manufacturing Engineering at The Pennsylvania State University – University Park. He heads the Systems for Hybrid – Additive Processing Engineering – The SHAPE Lab located in Innovation Park, Penn State. His research areas include additive and hybrid manufacturing, 3D Sand-Printing for novel metal casting processes, material development, and inter-disciplinary mechanical, biomedical and aerospace applications of additive manufacturing. Dr. Manogharan received his Ph.D. and M.S. in Industrial and Systems Engineering from North Carolina State University. He was awarded the 2018 International Outstanding Young Researcher in Freeform and Additive Manufacturing Award (FAME Jr), 2017 Society of Manufacturing Engineers’ Yoram Koren Outstanding Young Manufacturing Engineer Award and the 2016 Outstanding Young Investigator by Manufacturing and Design Division of Institute of Industrial and Systems Engineering.

Thanh Nguyen named the ACell Young Investigator Faculty Award Winner

Prof. Thanh Nguyen receives the highly regarded ACell Young Investigator Faculty Award at the 2020 Regenerative Medicine Workshop, which brings together leading experts from across the expansive field of regenerative medicine. Prof. Nguyen will deliver a keynote speech along with other world renowned researchers in the field of regenerative medicine during the event, which will take place at the Wild Dune Resort, South Carolina, in March 2020.

Prof. Thanh Nguyen receives the highly regarded ACell Young Investigator Faculty Award at the 2020 Regenerative Medicine Workshop, which brings together leading experts from across the expansive field of regenerative medicine. Prof. Nguyen will deliver a keynote speech along with other world renowned researchers in the field of regenerative medicine during the event, which will take place at the Wild Dune Resort, South Carolina, in March 2020.

Additional details are available through the workshop website.

Design for Additive Manufacturing: Three Use Cases and Their Implications

Abstract: A pattern is emerging among companies adopting metal-based additive manufacturing (AM). In the first stage, they use AM to replicate an existing part to understand the technology’s costs and capabilities. This gives them insight into AM processes and allows them to move onto the second stage wherein they adapt their designs for AM to reap more of its benefits—leveraging the design and material freedoms that AM affords. Finally, companies will shift to optimizing for AM as they gain confidence in an AM process while learning how to capitalize on AM to its full potential. These three stages can be effective when designing for AM, but only if expectations are carefully managed at each stage. Automotive, aerospace, consumer goods, and oil and gas examples from Penn State’s Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) are presented to illustrate the benefits and drawbacks of each stage. CIMP-3D served as the Manufacturing Demonstration Facility (MDF) for Additive Manufacturing for DARPA’s Open Manufacturing Program. In this role, CIMP-3D toured more than 6,000 visitors, organized a dozen technical forums and exchanges, and instituted the first hands-on industry practicum for metal AM. Efforts to educate the next generation workforce and (re)train the current workforce to use AM effectively and design for AM will also be discussed.

Abstract: A pattern is emerging among companies adopting metal-based additive manufacturing (AM). In the first stage, they use AM to replicate an existing part to understand the technology’s costs and capabilities. This gives them insight into AM processes and allows them to move onto the second stage wherein they adapt their designs for AM to reap more of its benefits—leveraging the design and material freedoms that AM affords. Finally, companies will shift to optimizing for AM as they gain confidence in an AM process while learning how to capitalize on AM to its full potential. These three stages can be effective when designing for AM, but only if expectations are carefully managed at each stage. Automotive, aerospace, consumer goods, and oil and gas examples from Penn State’s Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D) are presented to illustrate the benefits and drawbacks of each stage. CIMP-3D served as the Manufacturing Demonstration Facility (MDF) for Additive Manufacturing for DARPA’s Open Manufacturing Program. In this role, CIMP-3D toured more than 6,000 visitors, organized a dozen technical forums and exchanges, and instituted the first hands-on industry practicum for metal AM. Efforts to educate the next generation workforce and (re)train the current workforce to use AM effectively and design for AM will also be discussed.

Biographical Sketch: Dr. Simpson is the Paul Morrow Professor of Engineering Design & Manufacturing at Penn State with affiliate appointments in Architecture and Information Sciences & Technology. He serves as the co-Director of CIMP-3D (www.cimp-3d.org) and directs the world’s first interdisciplinary graduate program in Additive Manufacturing & Design. He has been PI or Co-PI on over $25M in funding for research in additive manufacturing and 3D printing, product family and product platform design, and multidisciplinary design optimization, including surrogate modeling and trade space exploration. He has published over 350 peer-reviewed journal and conference papers and 2 edited textbooks, and he contributes a monthly column to Modern Machine Shop called “Additive Insights”. He is a recipient of ASME’s Design Automation Award, Robert E. Abbott Award, and Ben C. Sparks Award as well as the ASEE Fred Merryfield Design Award. He has received numerous awards for outstanding research and teaching at Penn State, including the 2019 Teaching and Learning with Technology Impact Award. He is a Fellow in ASME and an Associate Fellow in AIAA. He chaired the ASME Design Engineering Division Executive Committee and the ASME Design, Manufacturing, and Materials (DMM) Segment Leadership Team. He helped ASME launch the Innovative Additive Manufacturing 3D (IAM3D) Design Challenge in 2014, and he served as the chair of ASME’s industry-focused Additive Manufacturing & 3D Printing Conference & Expo in 2015 and 2016. He received his Ph.D. and M.S. degrees in Mechanical Engineering from Georgia Tech and his B.S. in Mechanical Engineering from Cornell.

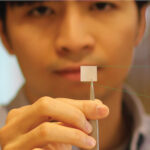

Buzzing Through the Blood-Brain Barrier

Prof. Thanh Nguyen’s research group has reported on the first biodegradable ultrasonic transducer that can help medication move from blood vessels into brain tissues and circumvent the body’s traditional defense mechanisms.The work is published in the journal of PNAS (Proceeding of National Academy of Science) (Dec 2019), and the two first authors of this paper are PhD students in Nguyen lab, namely Thinh Le and Eli Curry.

When implanted into the brain, this novel device can generate ultrasonic waves for buzzing drugs through the blood-brain barrier (BBB) to treat brain diseases (e.g. cancers), and then self-vanish, avoiding the need of invasive removal surgery that is often required for conventional medical implants. More details can be found in the UConn Today article.

Smart Surfaces: Integration of Flexible Electronics with Building Materials

Abstract: As one of the world’s largest electronic and building material suppliers, DuPont has many top brands and technologies in the areas of flexible hybrid electronics such as flexible/wearable conductive inks and films, and large-scale rigid and flexible substrates. Smart Materials in DuPont has been focusing on the convergence of electronics and building industries and produces a new category of integrated materials and Internet of Things end points. In this seminar, I’ll present a few of our prototypes and use cases on how we design and integrate sensing and actuations within the building and construction materials. These flexible electronic functionalities add the invisible features to the material surfaces and provide a new level of enhanced aesthetics, design options, and human-building interactions inside the buildings.

Abstract: As one of the world’s largest electronic and building material suppliers, DuPont has many top brands and technologies in the areas of flexible hybrid electronics such as flexible/wearable conductive inks and films, and large-scale rigid and flexible substrates. Smart Materials in DuPont has been focusing on the convergence of electronics and building industries and produces a new category of integrated materials and Internet of Things end points. In this seminar, I’ll present a few of our prototypes and use cases on how we design and integrate sensing and actuations within the building and construction materials. These flexible electronic functionalities add the invisible features to the material surfaces and provide a new level of enhanced aesthetics, design options, and human-building interactions inside the buildings.

Biographical Sketch: Dr. Wei Wu is Principal Investigator in the Electronics and Imaging business of DuPont. He is currently working in Smart Materials as a project technical lead and has developed many electronic technologies and integrated prototypes of building materials and electronics. He joined DuPont Central Research and Development in 2011 and has led a few R&D projects on photovoltaics, thin-film electronics, and wearables. Dr. Wu received his PhD and MS in Electrical Engineering at Northwestern University and his BS in Microelectronics at Peking University. He has published over 40 peer-reviewed articles and been invited to give many technical talks.

Radiation Chemistry, Reactivity and Dynamics in Ionic Liquids and Molten Salts

Abstract: Being comprised entirely of charged species, ionic liquids (IL) and molten salts (MS) have dramatically different properties compared to conventional molecular liquids and they provide new and unusual environments to test our understanding of physical chemistry phenomena. We are interested in how IL and MS properties influence physical and dynamical processes that determine the stability and lifetimes of reactive intermediates and thereby affect the courses of reactions and product distributions, for example in the areas of primary and applied radiation chemistry, radical chemistry and charge transfer reactions. A key issue in IL radiolysis is the competition between the solvation of the initially-formed excess electrons and the scavenging of electrons in different states of solvation. Pre-solvated electron scavenging is especially significant in ILs because their relatively high viscosities make their solvation dynamics 100-1000x slower than in conventional solvents. The slower relaxation dynamics of ILs make them excellent media for the general study of fundamental radiolysis processes, in combination with BNL’s Laser-Electron Accelerator Facility (LEAF) for picosecond pulse radiolysis studies. With LEAF we can observe the solvation processes of radiolytically- generated excess electrons and compare and contrast them with the mechanisms of pre-solvated electron scavenging. In molten salts, identifying the primary radiolysis products and characterizing their reactivities is important to understand the chemical evolution of the molten salt fuel over the duration of its lifetime in the reactor. Examples will be given of how the composition of the salt determines the identities and reactivities of the primary radiolysis products. The work on molten salts was supported as part of the Molten Salts in Extreme Environments Energy Frontier Research Center, funded by the U.S. Department of Energy Office of Science. The work on ionic liquids was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, Division of Chemical Sciences, Geosciences and Biosciences, under contract DE-SC0012704.

Abstract: Being comprised entirely of charged species, ionic liquids (IL) and molten salts (MS) have dramatically different properties compared to conventional molecular liquids and they provide new and unusual environments to test our understanding of physical chemistry phenomena. We are interested in how IL and MS properties influence physical and dynamical processes that determine the stability and lifetimes of reactive intermediates and thereby affect the courses of reactions and product distributions, for example in the areas of primary and applied radiation chemistry, radical chemistry and charge transfer reactions. A key issue in IL radiolysis is the competition between the solvation of the initially-formed excess electrons and the scavenging of electrons in different states of solvation. Pre-solvated electron scavenging is especially significant in ILs because their relatively high viscosities make their solvation dynamics 100-1000x slower than in conventional solvents. The slower relaxation dynamics of ILs make them excellent media for the general study of fundamental radiolysis processes, in combination with BNL’s Laser-Electron Accelerator Facility (LEAF) for picosecond pulse radiolysis studies. With LEAF we can observe the solvation processes of radiolytically- generated excess electrons and compare and contrast them with the mechanisms of pre-solvated electron scavenging. In molten salts, identifying the primary radiolysis products and characterizing their reactivities is important to understand the chemical evolution of the molten salt fuel over the duration of its lifetime in the reactor. Examples will be given of how the composition of the salt determines the identities and reactivities of the primary radiolysis products. The work on molten salts was supported as part of the Molten Salts in Extreme Environments Energy Frontier Research Center, funded by the U.S. Department of Energy Office of Science. The work on ionic liquids was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, Division of Chemical Sciences, Geosciences and Biosciences, under contract DE-SC0012704.

Biographical Sketch: James Wishart earned his Bachelors degree in Chemistry from the Massachusetts Institute of Technology (1979), and his Ph.D. in Inorganic Chemistry from Stanford University (1985) (Advisor: Henry Taube, Nobel Prize in Chemistry, 1983). Dr. Wishart is currently a Senior Chemist in the Chemistry Division of Brookhaven National Laboratory, where he has worked for 32 years. He has been studying the physical chemistry and radiation chemistry of ionic liquids, and recently molten salts, for 18 years. Dr. Wishart is currently the Director of the Molten Salts in Extreme Environments Energy Frontier Research Center. He is the leader of the BNL Accelerator Center for Energy Research (ACER), including the Laser-Electron Accelerator Facility (LEAF) for picosecond pulse radiolysis, which he also built in the 1990s. In September 2019, he received the Maria Skłodowska-Curie Medal from the Polish Radiation Research Society, for his distinguished achievements in the field of radiation chemistry and long-lasting and productive cooperation with Polish scientists.

Design, Build. Compete. UConn Formula SAE Among the Best in the World.

by Kassidy Manness

ME Communications

kassidy.manness@uconn.edu

Formula SAE Club ready for another exciting year of designing, building, and competing.

“Design. Build. Compete” is the motto that drives the determined and creative minds that make up the Formula SAE club here at UConn. Their club, consisting of many Mechanical Engineering students, is responsible for designing and building, all on their own, a formula style race car that is supposed to compete in two competitions by the time May rolls around.

Every season, the club, headed by president, Cara Connors, breaks up into subteams that are each responsible for one aspect of the car. An average meeting, which happens every Tuesday and Saturday, consists of the head of each subteam reporting out any updates, set backs, or solutions they have and saying what their next steps are. At this point in the year, the main thing each club member is working on is the design portion where they work on calculations and talk with the other subteams to make sure it will all work together. As the year continues, they will then focus more of the building and fabrication work before going into the testing of the car to ensure that it works. Everything is done by students, though; the driving, testing, and manufacturing, even though the do have some help from local and extended sponsors in order to help with the manufacturing costs and equipment.

Consistently, throughout the season, the club looks at the past models they have created and evaluate what went right and what can be developed further. Connors was able to mention a few of the changes and development they were making to the design this year, “Last year was the first year that we had an aerodynamic package, so an undertray on the car. We’re looking to develop that further, validating the design we had last year, and making it better for this upcoming year. We’re looking at better ways to mount that undertray. There’s a lot of weight optimization going on.”

Consistently, throughout the season, the club looks at the past models they have created and evaluate what went right and what can be developed further. Connors was able to mention a few of the changes and development they were making to the design this year, “Last year was the first year that we had an aerodynamic package, so an undertray on the car. We’re looking to develop that further, validating the design we had last year, and making it better for this upcoming year. We’re looking at better ways to mount that undertray. There’s a lot of weight optimization going on.”

What all of this ultimately leads up to for the club are two competitions, the Formula Michigan, which occurs in May, and the Formula North Competition, which happens in Ontario, Canada at the beginning of June. UConn’s club has done consistently well at each competition, but they usually base the success of their car on the Michigan competition, as it is the largest one. It, generally, has about 120 international teams that come out. This past year, UConn’s Formula SAE placed 11th out of the 120 teams. Connors said that they are hoping to crack the top 10 this year.

What all of this ultimately leads up to for the club are two competitions, the Formula Michigan, which occurs in May, and the Formula North Competition, which happens in Ontario, Canada at the beginning of June. UConn’s club has done consistently well at each competition, but they usually base the success of their car on the Michigan competition, as it is the largest one. It, generally, has about 120 international teams that come out. This past year, UConn’s Formula SAE placed 11th out of the 120 teams. Connors said that they are hoping to crack the top 10 this year.

At the competition, there is more than just racing that occurs in order to decide the winning cars. There are multiple dynamic events that they compete in to test the car’s physical performance in acceleration, skidpad, autocross, and endurance. There are also static events that are evaluated to look at the cars design presentation, business marketing presentation, cost report, and fuel economy.

At the competition, there is more than just racing that occurs in order to decide the winning cars. There are multiple dynamic events that they compete in to test the car’s physical performance in acceleration, skidpad, autocross, and endurance. There are also static events that are evaluated to look at the cars design presentation, business marketing presentation, cost report, and fuel economy.

Formula SAE is open to any major, not just Mechanical Engineers. They meet every Tuesday at 6:30 pm and Saturday at 12 pm at their shop on Depot Campus. For any interested, new members, you can go to the Visitor’s Center and be picked up by club members thirty minutes before the meeting begins. If you have any other questions, you can email the president, Cara Connors, at cara.connors@uconn.edu.