Prof. Julian Norato is developing computational techniques for welded plate structures in conjunction with Caterpillar, Inc. These techniques can be a powerful design tool to explore the design of structures from a blank sheet.

Dr. Norato with his student Shanglong Zhang, with funding from Caterpillar, are developing computational techniques for the design of structures made of welded plates, such as those encountered in large structures for heavy machinery and ship structures.

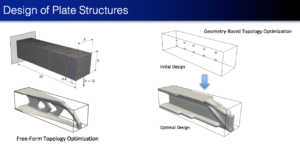

Their work is focused on topology optimization — a computational technique that determines the optimal spatial distribution of material within a space envelope to, for example, design the lightest structure that will not mechanically fail under applied loads. This technique is a powerful engineering design tool to explore the design of structures starting from a blank sheet. Existing topology optimization techniques produce complex, organic designs that cannot be readily fabricated by welding plates. In order to be most economical, this current process in many cases results in the production of large, strong structures typically made of steel. This is the case with the main structures of heavy machinery and ships. Dr. Norato’s topology optimization method renders designs that are made exclusively of constant-thickness plates which can be welded, which greatly facilitates the translation of the topology optimization result to a design concept of the structure that is amenable to fabrication.